Wij Maken Unieke Grote & Gedetailleerde Objecten

Productie van:

Modellen

Van kunstobjecten en props tot complete mannequins en gevel elementen.

Prototypes

Gedetailleerde prototypes, maquettes en mock-ups die perfect zijn om een nieuw idee te verkopen.

Tooling

Snelle en efficiente productie van mallen voor verschillende productieprocessen.

Onze Markten

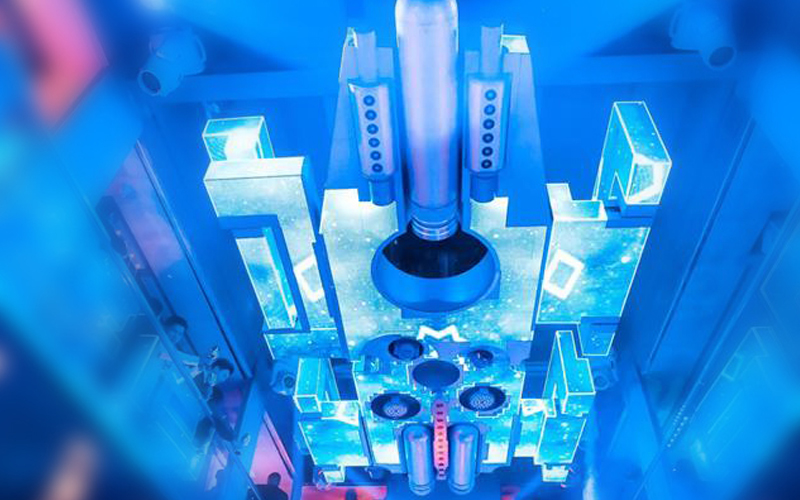

Visuele marketing

Eye-catchers en blowups voor winkels en horeca. Unieke figuren voor marketing campagnes met grote impact.

Sinds Fiberneering gietmallen in polyurethaan voor ons produceert, als alternatief voor gefreesde aluminium mallen, besparen wij niet alleen op gereedschapskosten. Door de drastische gewichtsvermindering van gietmallen in hars hebben wij ook geen hijswerktuigen en middelen voor intern transport meer nodig, waardoor de gietcycli met de helft worden verkort.

Wanneer we voor uitdagingen staan met betrekking tot complexe geometrie die simpelweg te tijdsintensief of fysiek niet mogelijk is om op onze 5-assige freesmachine te produceren, zijn we altijd blij dat we kunnen vertrouwen op de grote harsprinters van Fiberneering. Voor ingewikkelde objecten tot 1 of 2 meter vormen zij een perfecte aanvulling op ons werkgebied.

Voor de eenmalige productontwikkeling van onze nieuwste gangway voor superjachten bleken de grootformaat printmogelijkheden van Fiberneering echt een perfecte oplossing te zijn. Het helpt ook dat de werktuigbouwkundigen en scheepsbouwkundigen van Fiberneering altijd graag meedenken over efficiëntere manieren om te produceren.

Unieke Mogelijkheden met 3D Printen

In onze productie gebruiken wij voornamelijk speciale 3D printers van het type XXL-DLP. Hiermee kunnen we relatief snel grote objecten printen met veel detaillering. Dit is perfect voor de producten die wij maken. Deze printers werken met vloeibare harsen die uitgehard worden met UV licht. Dit proces wordt Stereolithografie of DLP printen genoemd. Het is het meest efficiente proces voor gedetailleerde producten groter dan 100mm.

Grote 3D prints

Prints in één stuk tot 1 x 0.5 x 0.5m, welke gecombineerd kunnen worden tot grotere formaten. Dit maakt het mogelijk om levensgrote figuren te maken met echte impact!

Scherpe details

Details zijn van groot belang voor realisme en expressie. Scherpe hoeken en overhangende delen kunnen niet gemaakt worden uit mallen. Hiervoor is printen met onze 150 micrometer resolutie perfect.

Klaar om af te werken

Onze prints kunnen met de meeste coatingsystemen afgewerkt worden om unieke modellen te creëren. De hoge kwaliteit van de harscomponenten zorgt voor lange duurzaamheid, zowel buiten als binnen.

Hoe Wij Werken

Wij hebben onze eigen productiefaciliteit in Zwolle. Hier kunnen wij ontwerpen, engineeren, produceren en nabewerken. Als er complexere bewerkingen nodig zijn, dan werken we samen met gevalideerde partners om zo telkens de juiste eindproducten te kunnen leveren.

Projecten

Het grootste deel van onze werkzaamheden verichten wij op projectbasis. Hierbij kunnen we de volledige productie van design en engineering tot aan afwerking en installatie verzorgen.

Cusomised Serie Producties

Voor repeterende opdrachten (zelfs als het product telkens iets veranderd) kunnen wij op contractbasis produceren. Denk hierbij bijvoorbeeld aan de productie van gepersonaliseerde beeldjes op basis van 3D scans.

Enkel stuks printopdrachten

En uiteraard kunnen wij ook 3D prints leveren op basis van een model dat aangeleverd wordt

Laten we samen iets bouwen

Wij werken graag met u samen op uw volgende project! Of u nu op zoek bent voor een enkele print of als u 3D printen wilt inzetten in uw huidige productieproces, wij komen graag in contact!